The Ultimate Guide to Buying a 20‑ft Container: What You Need to Know Before You Click “Add to Cart”

If you’re reading this, chances are you’re on the hunt for a 20‑ft container for sale. Whether you need a sturdy storage solution for your workshop, a mobile office for a construction site, or a shipping container to start a small‑scale import‑export business, the 20‑ft (also called “20‑foot”) container is the most versatile size on the market.

In this guide you’ll discover:

- The key dimensions and specifications you should verify before purchasing.

- How to compare new vs. used containers and spot hidden costs.

- The top reasons people buy a 20‑ft container and which features matter most for each use‑case.

- A quick‑reference table that breaks down the most common options.

- FAQs that answer the burning questions you probably haven’t thought to ask yet.

Grab a coffee, settle in, and let’s walk through everything you need to know so you can make an informed decision and avoid buyer’s remorse.

1. Why a 20‑ft Container?

1.1 The Sweet Spot of Size

A 20‑ft container offers approximately 1,172 cubic feet (33.2 m³) of internal volume. That’s enough space to:

| Use‑Case | Approx. Volume Needed | Why a 20‑ft Works |

|---|---|---|

| Home inventory storage | 800 ft³ | Leaves room for aisles and easy access |

| Mobile office | 600 ft³ | Fits a desk, chairs, and wiring without feeling cramped |

| Small‑scale e‑commerce fulfillment | 1,000 ft³ | Holds a few pallets of product while still being portable |

| DIY workshop | 900 ft³ | Allows room for tools, a workbench, and raw material bins |

Because it’s half the length of a 40‑ft container, it’s easier to maneuver through narrow alleyways, residential driveways, and smaller shipping yards—while still giving you a decent amount of space.

1.2 Global Standardization

All 20‑ft containers adhere to ISO 668 dimensions, which means they can be stacked, transported by ship, rail, or truck, and fit into standard container handling equipment worldwide. If you ever need to move the container across borders, you’re already speaking the universal language of logistics.

1.3 Cost‑Effectiveness

A new 20‑ft container typically costs $2,500–$4,000 (depending on material and accessories). Used units can be found for $1,200–$2,500, giving you a huge price‑performance ratio compared with building a custom shed or renting a storage unit.

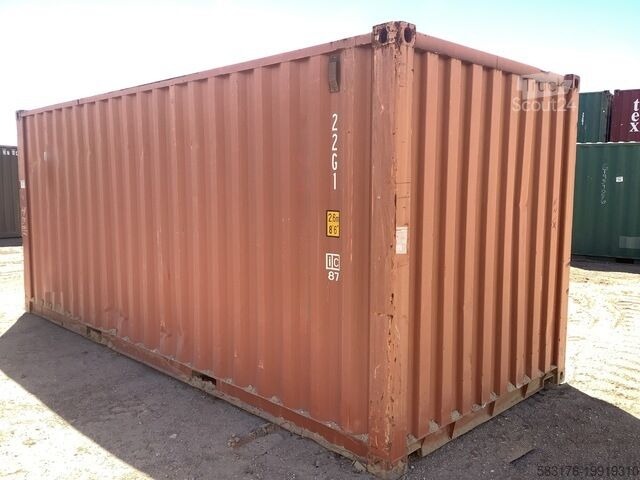

2. New vs. Used: Which Should You Choose?

| Factor | New Container | Used Container |

|---|---|---|

| Price | Higher upfront cost | Lower price |

| Condition | Pristine, no dents, fresh paint, full warranty | May have dents, rust, or previous modifications |

| Customization | Easy to add doors, windows, insulation before delivery | May need repair before any upgrades |

| Delivery Lead‑Time | 2–4 weeks (factory to dock) | 1–2 weeks (local vendor) |

| Resale Value | Higher, retains 80‑90 % of original value after 5 years | Lower, depreciation already occurred |

| Warranty | 1–2 years structural warranty | Usually “as‑is”, no warranty |

Quick tip: If you plan to use the container for a temporary or low‑risk storage solution, a used unit is often the smartest choice. For a mobile office, retail pop‑up, or anything that will be seen by clients, a new container presents a professional image and reduces the chance of unexpected repairs.

3. What to Inspect Before You Sign the Deal

Even if you buy a brand‑new container, it’s worth checking a few details to avoid surprises later on. Use this checklist when you walk the lot or inspect a listing online:

- Exterior Condition – Look for dents, rust spots, and broken corners. A few minor scratches are fine, but large rust patches can weaken the structure.

- Door Alignment & Seals – Open and close the doors. They should slide smoothly and seal tightly; any gaps may lead to water infiltration.

- Flooring – Verify the floor is solid, free of holes, and does not flex under weight.

- Ventilation – Most containers include small vents; ensure they are not clogged.

- Documentation – Ask for a Certificate of Ownership (CO), a Container Inspection Report (CIR), and any maintenance logs if it’s used.

- Load‑Bearing Capacity – Standard containers are rated for 30 t (66,000 lb) stacking weight and 28 t (61,600 lb) static load. Confirm this matches your intended use.

4. Customization Options That Add Real Value

A plain steel box is functional, but most buyers want something that fits their brand or operational needs. Below are the most popular upgrades and their typical price ranges (prices are approximate and vary by location).

| Upgrade | Description | Typical Cost (USD) |

|---|---|---|

| Insulation | Spray‑foam or panel insulation (R‑value 13–19) for temperature control | $500–$1,200 |

| Electrical Wiring | LED lighting, outlets, and a breaker panel for office use | $300–$800 |

| Windows & Skylights | 1–2 tempered glass windows (6×6 in) + optional skylight | $200–$600 |

| Doors | Roll‑up, swing, or side‑opening doors (steel, insulated) | $400–$1,500 |

| Floor Coating | Epoxy or polyurethane coating for durability | $250–$700 |

| Exterior Paint | Custom color, graphics, or branding wraps | $300–$1,000 |

| Ventilation Fans | Automated roof or side-mounted fans for airflow | $150–$400 |

| Security | Locking mechanisms, CCTV, or alarm system | $100–$500 |

If you’re planning a mobile office, pairing insulation with electrical wiring and a few windows typically yields the most comfortable workspace. For a storage unit, a simple floor coating and exterior paint might be sufficient.

5. How to Choose the Right Supplier

Not all container dealers are created equal. Below are the three main types of suppliers and the pros/cons of each.

| Supplier Type | Advantages | Disadvantages |

|---|---|---|

| Large‑Scale Importer (e.g., Shanghai Shipping Co.) | Bulk pricing, guaranteed ISO compliance, global network | Minimum order quantities, longer shipping times |

| Local Dealer / Refurbisher (e.g., City Container Solutions) | Quick delivery, can see the container in person, easier negotiations | May have limited inventory, quality varies |

| Online Marketplace (e.g., eBay, ContainerAuction.com) | Wide selection, price comparison tools | Risk of scams, variable inspection standards, shipping logistics left to buyer |

Pro tip: When possible, request a video walk‑through of the container before purchase and ask for the ISO certification number. Reputable sellers will gladly provide detailed photos, reports, and references.

6. Calculating the True Cost of Ownership

It’s tempting to focus solely on the purchase price, but the total cost of ownership (TCO) includes several hidden items:

| Cost Category | Example Items | Frequency |

|---|---|---|

| Purchase Price | New or used container cost | One‑time |

| Delivery & Placement | Trucking, crane rental, foundation prep | One‑time |

| Customization | Insulation, electrical, paint | One‑time |

| Insurance | Cargo or property insurance for the container | Annual |

| Maintenance | Rust treatment, door lubrication, floor repairs | As needed |

| Permits & Zoning | Local building permits if used as a structure | One‑time |

Sample TCO Breakdown (New 20‑ft container, basic office fit‑out):

| Item | Cost (USD) |

|---|---|

| Container (new) | $3,200 |

| Delivery (30 mi) | $600 |

| Insulation + Electrical | $1,200 |

| Exterior Branding Paint | $500 |

| Permit & Inspection | $250 |

| First‑Year Insurance | $150 |

| Total First‑Year Cost | $5,900 |

Later years will mostly involve insurance and occasional maintenance, typically $150–$300 per year. Knowing these numbers up front helps you budget accurately and avoid surprise expenses.

7. Frequently Asked Questions (FAQ)

Q1: How long does a 20‑ft container last?

A: With proper maintenance (regular cleaning, rust treatment, and protective paint), a steel container can easily exceed 25–30 years. The structural frame remains sound much longer than the interior finish.

Q2: Can I place a container on a concrete slab?

A: Absolutely. A flat, level surface such as a concrete pad is ideal because it prevents moisture wicking and distributes weight evenly. For temporary setups, a compacted sand base with wood sleepers works too.

Q3: Do I need a permit to install a container on my property?

A: It depends on local zoning laws. Many municipalities treat containers as accessory structures, requiring a building permit if the container will be used as a workspace, living area, or retail space. Check with your city planning department.

Q4: What is the difference between a “dry container” and a “reefer”?

A: A dry container (the standard you’re looking at) is uninsulated and has no temperature control. A “reefer” is a refrigerated unit with built‑in cooling systems, typically used for perishable goods. Reefer containers cost 2‑3× more.

Q5: How do I secure a container against theft?

A: Use a high‑security lock set (ISO 9001‑rated), add a steel door brace, install a CCTV system, and consider a GPS tracker. For high‑value contents, a reinforced roof lock and perimeter fencing add extra layers of protection.

Q6: Can I stack a 20‑ft container on top of a 40‑ft container?

A: Yes, as long as the containers are rated for stacking (most are). The lower container must be capable of bearing the combined weight—typically 30 t. Ensure both containers are in good structural condition.

Q7: How far can a 20‑ft container be shipped overseas?

A: Practically anywhere with a port. Shipping costs are calculated by volume (cubic meters) and distance. A typical trans‑pacific shipment for a 20‑ft container runs $1,200–$2,000 door‑to‑door (excluding customs duties).

8. Step‑By‑Step Buying Process (A Quick Checklist)

- Define Your Use‑Case – Storage, office, retail, or specialty (e.g., workshop).

- Set a Budget – Include purchase price + TCO items.

- Research Suppliers – Compare at least three options; ask for quotes and ISO certs.

- Inspect the Container – Use the inspection checklist above.

- Negotiate Customizations – Decide on insulation, doors, paint, etc., and get a written quote.

- Arrange Delivery – Confirm site access, foundation prep, and crane availability if needed.

- Secure Permits – Apply for any local building or zoning permits before placement.

- Finalize Payment – Use a secure method (escrow or bank transfer) and obtain a receipt and CO (Certificate of Ownership).

- Installation & Fit‑Out – Schedule any electrical or interior work.

- Maintain – Perform a visual inspection every 6 months; treat any rust spots promptly.

Following these steps will help you move from “browsing containers online” to “enjoying your new 20‑ft space” without a hitch.

9. Real‑World Examples: How Others Use Their 20‑ft Containers

- Urban Pop‑Up Café – A coffee truck owner bought a new 20‑ft container, added a side‑opening door, insulated walls, and a small kitchen layout. The result? A fully licensed food service space that slides into alleyways where a traditional brick building could not fit.

- Home Renovation Storage – A DIY enthusiast placed a used container behind his house, painted it matte gray, and used it to store lumber, paint cans, and power tools for a year-long remodel. The cost? Under $2,000 total, saving $500+ in monthly self‑storage fees.

- Small‑Scale Shipping Hub – An e‑commerce startup imported a refurbished container, fitted it with a pallet racking system, and turned it into a fulfillment center. The container’s ISO compliance allowed seamless integration with their carrier’s logistics platform.

These stories illustrate how flexible a 20‑ft container can be when you align the right features with your purpose.

10. Final Thoughts – Your Next Move

You now have a solid foundation to evaluate, compare, and purchase a 20‑ft container for sale with confidence. Remember:

- Match the container type to your application (new vs. used, basic vs. customized).

- Look beyond the sticker price—consider delivery, permits, and future maintenance.

- Inspect thoroughly and demand the proper documentation before finalizing the deal.

- Plan for customization early, as adding insulation, wiring, or windows after delivery can become more expensive.

When you’re ready, start by listing your top three suppliers, request detailed quotes, and schedule a virtual or in‑person walkthrough. Within a few weeks, you could be standing in front of your brand‑new (or freshly refurbished) 20‑ft container, ready to turn it into the exact space you imagined.

Happy container hunting! 🚢🏗️