The Ultimate Guide to Building a Container House

Your roadmap from concept to completion

Introduction – Why a Container House Might Be Your Perfect Home

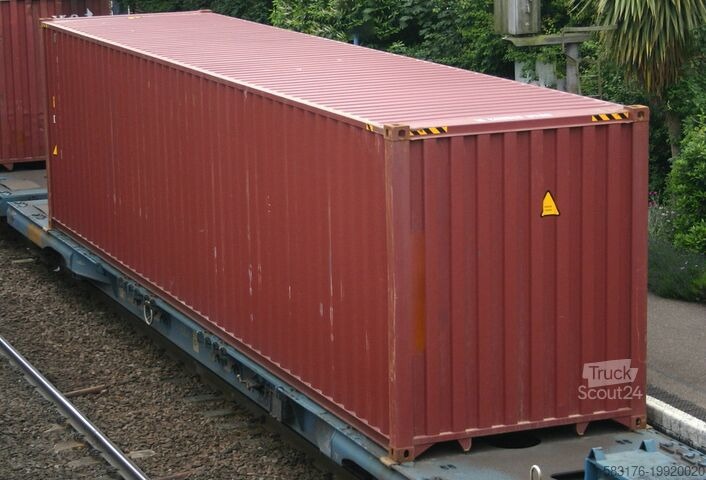

You’ve probably seen those sleek, box‑shaped homes popping up in urban infill projects, beach‑side retreats, and even luxury resorts. A container house—a dwelling made from one or more repurposed shipping containers—offers a unique blend of affordability, speed of construction, and eco‑friendliness.

If you’re a first‑time homeowner, a tiny‑house enthusiast, or a developer looking for a modular solution, this guide will walk you through everything you need to know, from budgeting and design to permits and maintenance. By the end, you’ll have a clear, actionable plan to turn a steel box into a comfortable, stylish living space.

1. What Makes a Container House Different?

| Feature | Traditional Build | Container Build |

|---|---|---|

| Core Structure | Wood‑frame or concrete | Steel shipping container (ISO‑standard) |

| Construction Time | 6‑12 months (or more) | 8‑16 weeks (including interior fit‑out) |

| Material Waste | High (excess lumber, drywall) | Low (re‑used container) |

| Thermal Mass | Moderate (depends on insulation) | High (steel transfers heat quickly) |

| Mobility | Fixed | Potentially relocatable (subject to local codes) |

| Cost per Sq ft | $150‑$250 | $100‑$180 (excluding interior finishes) |

Key takeaway: The container’s steel shell is the “ready‑made” skeleton of your home, which slashes both material costs and construction timelines. However, the steel’s conductivity means you’ll need a thoughtful approach to insulation and ventilation.

2. Choosing the Right Container(s)

2.1 Size Matters

| Container Type | Interior Dimensions (L × W × H) | Approx. Square Footage |

|---|---|---|

| 20‑Foot (Standard) | 19.4 ft × 7.9 ft × 8.5 ft | ~155 sq ft |

| 40‑Foot (Standard) | 39.5 ft × 7.9 ft × 8.5 ft | ~310 sq ft |

| 40‑Foot (High Cube) | 39.5 ft × 7.9 ft × 9.5 ft | ~350 sq ft |

When you stack or combine containers, you can create anything from a compact studio to a multi‑room family home. The “high‑cube” version adds an extra foot of headroom—great for lofts or taller ceilings.

2.2 New vs. Used

| Criteria | New Containers | Used Containers |

|---|---|---|

| Price | $4,500‑$6,500 per 40‑ft | $2,500‑$4,000 per 40‑ft |

| Condition | Pristine, no dents | May have dents, rust, or previous modifications |

| Lead Time | 2‑4 weeks (if stocked) | 1‑2 weeks (local scrap yard) |

| Warranty | Manufacturer warranty | None (inspect thoroughly) |

If you’re on a tight budget, a well‑inspected used container can be a great choice. Just make sure to verify structural integrity—no severe rust, bent corners, or compromised welds.

3. Core Design Considerations

3.1 Layout Planning

- Define Your Zones – Living, sleeping, kitchen, bathroom, storage.

- Stack or Side‑By‑Side? – Stacking adds height (good for lofts); side‑by‑side creates a wider floor plan.

- Cutting Openings – Plan where windows, doors, and skylights will go. Remember that each cut reduces structural rigidity, so you’ll need reinforcement (steel beams or “strong‑backs”).

3.2 Insulation & Energy Efficiency

| Insulation Type | R‑Value (per inch) | Pros | Cons |

|---|---|---|---|

| Spray‑Foam (Closed‑Cell) | 6‑7 | Air‑tight seal; adds structural strength | Higher cost |

| Rigid Foam Board (XPS) | 5 | Easy to install; good moisture resistance | Requires interior finish |

| Batt Insulation (Fiberglass) | 3.5 | Inexpensive; familiar to DIY | Needs vapor barrier; less effective on steel |

A common strategy is to combine spray‑foam on the exterior (for airtightness) with rigid foam board inside the walls, then finish with drywall or wood paneling.

3.3 Ventilation & Moisture Control

- Mechanical Ventilation: Install HRVs (Heat Recovery Ventilators) to supply fresh air while retaining heat.

- Dehumidifiers: Essential in humid climates, especially during the first few months while the building “settles.”

- Roof Overhangs: Add a modest overhang (12‑18 in) to shield windows from rain and solar gain.

4. Budget Breakdown – What to Expect

Below is a realistic cost estimate for a 40‑foot high‑cube container house (≈350 sq ft). Prices are averages for 2024–2025 in the United States; adjust for local market conditions.

| Category | Estimated Cost (USD) | % of Total Budget |

|---|---|---|

| Container (used, high‑cube) | $3,200 | 12% |

| Site Preparation (foundation, grading) | $5,500 | 20% |

| Structural Reinforcement (steel beams, welding) | $2,800 | 10% |

| Insulation (spray‑foam + rigid board) | $4,200 | 15% |

| Interior Finishes (drywall, flooring, paint) | $6,300 | 23% |

| Electrical & Plumbing | $3,100 | 11% |

| Fixtures & Appliances | $2,000 | 7% |

| Permits & Design Fees | $1,200 | 4% |

| Total | $28,400 | 100% |

Tip: Allocate a contingency fund of 10–15% for unexpected expenses (e.g., additional steel reinforcement or design changes).

5. Step‑by‑Step Checklist

| Phase | Action Item | Details |

|---|---|---|

| Planning | Secure a building lot | Check zoning, setbacks, and access roads |

| Obtain permits | Building, electrical, plumbing—consult your local authority | |

| Choose container configuration | 1‑2 × 40‑ft high‑cube is popular for a 2‑bed layout | |

| Site Work | Lay foundation | Concrete slab, pier & beam, or steel footings |

| Deliver containers | Use a crane or forklift; ensure level placement | |

| Structural | Cut openings | Doors, windows, HVAC ducts — reinforce with steel headers |

| Add reinforcement | Install cross‑bracing or “strong‑backs” where cuts occur | |

| Envelope | Install insulation | Spray‑foam on exterior; rigid board inside walls |

| Apply weather barrier | House wrap or EPDM membrane | |

| Interior | Frame interior walls (if any) | 2×4 timber or steel studs |

| Install utilities | Rough‑in plumbing, electrical, and HVAC | |

| Finish surfaces | Drywall, flooring, cabinetry | |

| Final Touches | Paint & decorate | Choose low‑VOC paints for health |

| Install fixtures | Lighting, bathroom, kitchen appliances | |

| Conduct final inspection | Obtain occupancy certificate |

6. Sustainability Benefits

- Reduced Carbon Footprint: Re‑using a container prevents a new steel product from entering the market, saving up to 1.5 tons of CO₂ per container.

- Material Efficiency: Minimal waste—most cuts are reclaimed for scrap metal.

- Energy‑Efficient Design: With proper insulation and passive solar orientation, a container house can achieve Passive House standards, slashing heating/cooling loads.

If you’re passionate about green living, consider adding solar panels, rainwater harvesting, and composting toilets to round out your eco‑friendly lifestyle.

7. Common Legal Hurdles

- Zoning Restrictions – Some municipalities classify container homes as “accessories” or “non‑residential” structures.

- Building Codes – Steel containers must meet local fire‑resistance, structural, and energy codes.

- Height Limits – Stacked containers can breach height restrictions; check with planning departments early.

Pro tip: Hire a local architect or engineer familiar with modular construction—they can often navigate code variances faster than you can on your own.

8. Frequently Asked Questions (FAQ)

| Question | Answer |

|---|---|

| Can I move a container house after it’s built? | Technically yes, but you’ll need a crane, a new foundation, and a permit for relocation. It’s easier to design the house as a mobile unit from the start (e.g., using a trailer chassis). |

| How long does a container house last? | With proper maintenance (preventing rust, sealing joints, and managing moisture), the steel shell can last 30‑50 years, comparable to conventional homes. |

| Do I need a professional to cut the steel? | It’s strongly recommended. Cutting and welding affect structural integrity; a certified fabricator will ensure the work complies with engineering standards. |

| Is it safe in earthquakes or hurricanes? | Steel frames are inherently strong and can be engineered for seismic loads. For hurricane zones, reinforce connections, add hurricane straps, and install impact‑rated windows. |

| What about insulation—won’t it make the interior cramped? | Insulation does reduce interior dimensions slightly (usually 2‑4 in per wall). Designing slightly larger containers or adding an interior “stud wall” can offset loss of space. |

| Can I add a second story? | Yes, by stacking containers and installing a robust structural system (e.g., steel trusses). You’ll need to meet local height and load‑bearing requirements. |

| How much does it cost per square foot? | Roughly $80‑$100 per sq ft for a basic finish; upscale finishes can push it to $150‑$180 per sq ft. |

9. Final Thoughts – Your Path to a Container Home

You now have a comprehensive blueprint: from selecting the right container and budgeting wisely, to tackling design nuances and navigating permits. Building a container house isn’t just a cost‑saving exercise; it’s a statement about resourcefulness, modern aesthetics, and sustainable living.

Ready to get started? Begin by scouting a suitable lot, sketching a rough floor plan, and reaching out to a local architect who’s familiar with modular construction. The sooner you lock down the permits, the faster the steel will arrive, and the sooner you’ll be stepping into your brand‑new, environmentally conscious home.

Happy building, and enjoy the satisfaction of turning a humble shipping box into a place you’ll call yours.