Shipping Container Sizes: The Complete Guide for Anyone Who Needs to Move, Store, or Build

When you hear the word “container,” the first image that pops into your mind is probably a massive steel box stacked on a dock, waiting to be loaded onto a ship. But a shipping container is far more than a simple metal crate—it’s a versatile, globally standardized system that can be used for everything from international freight to pop‑up shops, tiny homes, and on‑site storage.

If you’re trying to decide which container size is right for you, you’ve come to the right place. This guide walks you through every major container dimension, explains how the numbers translate into real‑world space, and gives you the tools you need to make an informed choice.

1. Why Container Dimensions Matter

Before we dive into the data, it’s worth understanding why the size of a container matters to you:

| Reason | How Size Impacts Your Project |

|---|---|

| Capacity | Larger containers hold more cargo, but they may be overkill for a small renovation. |

| Transport Costs | Most shipping lines price freight by TEU (twenty‑foot equivalent unit). Bigger containers can sometimes be more cost‑effective per cubic foot. |

| Site Constraints | A 53‑ft container may not fit through a narrow gate or onto a small trailer. |

| Weight Limits | Each size has a maximum payload (e.g., 28,000 lb for a 20‑ft dry container). Over‑loading can lead to fines or safety hazards. |

| Regulations | Some countries impose length restrictions on road transport; knowing the exact dimensions helps you stay compliant. |

Understanding these points will help you avoid costly mistakes down the line.

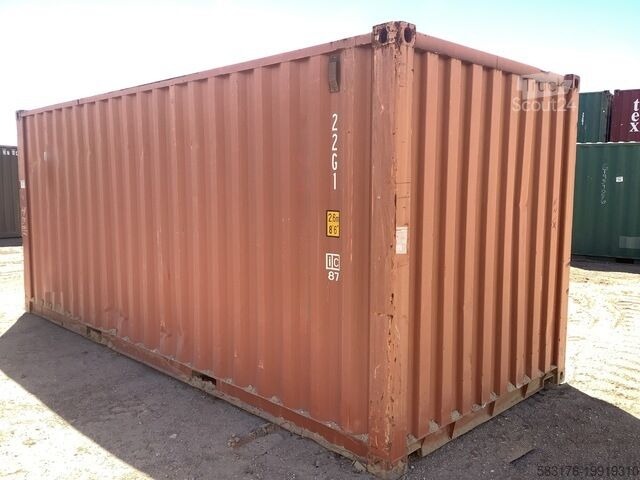

2. The Core Family: Standard Dry Containers

The “dry container” (also called a General‑Purpose Container, or GP) is the workhorse of global trade. It’s the classic rectangular box you see on cargo ships and at construction sites.

| Size | Inside Length (ft) | Inside Width (ft) | Inside Height (ft) | Inside Volume (cu ft) | Max Payload (lb) |

|---|---|---|---|---|---|

| 20‑ft (Standard) | 19.4 | 7.8 | 7.9 | 1,172 | 48,000 |

| 20‑ft (High Cube) | 19.4 | 7.8 | 8.9 | 1,300 | 48,000 |

| 40‑ft (Standard) | 39.5 | 7.8 | 7.9 | 2,390 | 59,000 |

| 40‑ft (High Cube) | 39.5 | 7.8 | 8.9 | 2,570 | 59,000 |

| 45‑ft (High Cube) | 44.5 | 7.8 | 8.9 | 2,865 | 62,000 |

| 48‑ft (High Cube) | 47.5 | 7.8 | 8.9 | 3,200 | 62,000 |

| 53‑ft (High Cube) | 52.8 | 8.4 | 9.0 | 3,730 | 66,500 |

All measurements are interior; exterior dimensions are roughly 1–2 in larger on each side.

Key takeaways

- 20‑ft containers are perfect for small‑scale moves, hobby‑ist projects, or as a portable workshop.

- 40‑ft containers are the sweet spot for most commercial freight—big enough for a full truckload but still widely accepted at ports worldwide.

- High‑cube (HC) containers add an extra foot of height, giving you roughly 10 % more volume without a dramatic increase in footprint.

- 45‑ft, 48‑ft, and 53‑ft units are popular in North America for domestic freight and for converting into living spaces because they allow a more spacious interior while still fitting on a standard trailer.

3. Specialty Containers: When the Standard Won’t Do

If your project involves temperature control, oversized cargo, or a need for easy loading, you’ll likely step outside the GP family. Below are the most common specialty types.

| Type | Typical Length | Inside Dimensions (L×W×H) | Special Feature |

|---|---|---|---|

| Refrigerated (Reefer) | 20 ft, 40 ft | Same as GP + insulated walls | Powered cooling for perishables |

| Open‑Top | 20 ft, 40 ft | Same footprint, no fixed roof | Easy loading of tall items (e.g., pipes) |

| Flat‑Rack | 20 ft, 40 ft | Deck + collapsible sides | Carries oversized loads like machinery |

| Ventilated (Vent) | 20 ft, 40 ft | Same as GP | Built‑in vents for organic products |

| Insulated | 20 ft, 40 ft | Same as GP | Maintains stable temperature without active cooling |

| Half‑Height | 20 ft, 40 ft | Half the interior height | Used for bulk solids (e.g., sand, grain) |

Pro tip: If you need a container for a project that will stay on a single site for months, a high‑cube or insulated unit often offers the best balance of space and comfort.

4. How to Choose the Right Size for Your Project

Below is a step‑by‑step checklist you can follow when evaluating which container works best for you.

- Calculate Required Volume

- List every item you plan to store or transport.

- Convert each item’s dimensions to cubic feet (L × W × H).

- Add a 10‑15 % buffer for packing material and movement.

- Check Weight Restrictions

- Sum the weight of all items.

- Compare to the payload limits in the table above.

- Remember that the container itself weighs ~4,800 lb (20‑ft) to ~5,600 lb (40‑ft).

- Assess Site Access

- Measure gate widths, driveway turns, and any overhead clearances.

- Verify that a crane, forklift, or tractor trailer can handle the container’s length and weight.

- Consider Future Flexibility

- If you anticipate growth, choose a size that can be easily combined (e.g., two 20‑ft containers can become a 40‑ft unit when placed side‑by‑side).

- High‑cube containers add height without changing the footprint—great for vertical projects.

- Budget & Shipping Costs

- Freight charges are often quoted per TEU. A 40‑ft container (2 TEU) may cost less per cubic foot than a single 20‑ft unit.

- Factor in any additional fees for specialty containers (reefer, open‑top, etc.).

- Regulatory Compliance

- If you’re moving the container across state or national borders, check local road‑transport length limits (e.g., many European countries cap road‑legal containers at 40 ft).

- Verify any required permits for oversized loads.

5. Real‑World Use Cases

To illustrate how size choices play out in practice, here are a few common scenarios:

| Scenario | Recommended Container(s) | Why It Fits |

|---|---|---|

| Home Renovation Storage | One 20‑ft HC or two 20‑ft standard | Provides enough space for lumber, tiles, and tools while staying portable. |

| Pop‑Up Retail Shop | One 40‑ft HC | The extra height lets you install shelving and a small changing room. |

| Mini‑Warehouse for a Startup | Two 40‑ft HC + one 20‑ft standard | Enables separate zones for inventory, packaging, and office space. |

| Shipping Fresh Produce | 40‑ft Reefer | Keeps temperature stable over long hauls and offers ample volume. |

| Construction of a Tiny Home | One 45‑ft or 53‑ft HC | Gives you a livable floor plan with enough height for standing room and loft space. |

| Transporting Heavy Machinery | One 40‑ft Flat‑Rack | The collapsible sides allow loading of oversized equipment without disassembly. |

6. FAQs About Shipping Container Sizes

Q1: What does “TEU” stand for and why should I care?

Answer: TEU means “Twenty‑foot Equivalent Unit.” One 20‑ft container = 1 TEU; a 40‑ft container = 2 TEU. Shipping lines price freight based on TEUs, so understanding this helps you estimate shipping costs accurately.

Q2: Can I combine two 20‑ft containers to make a 40‑ft unit?

Answer: Physically you can place two 20‑ft units side‑by‑side or end‑to‑end, but they remain separate containers. If you need a single, continuous interior space, you must purchase a genuine 40‑ft container.

Q3: Are high‑cube containers more expensive?

Answer: Slightly. The price premium ranges from 5‑10 % over standard containers because of the extra steel and increased interior volume. The extra space often justifies the cost, especially for living‑space conversions.

Q4: What is the maximum legal length for a container on U.S. highways?

Answer: Standard regulations allow up to 53 ft (the most common “semi‑tractor trailer” length). Anything longer requires special permits and may be restricted on certain routes.

Q5: How do I modify a container without voiding warranties or certifications?

Answer: For most modifications (cutting doors, adding windows), you should work with a certified container conversion specialist. They’ll preserve structural integrity and maintain compliance with ISO standards.

Q6: Do I need a special license to transport a 40‑ft container?

Answer: In the U.S., a regular commercial driver’s license (CDL) Class A is sufficient for pulling a standard tractor‑trailer with a 40‑ft container. However, check state‑specific rules, especially if you plan to use a 45‑ft or larger unit.

Q7: Can I stack containers of different sizes safely?

Answer: Yes, provided they’re designed for stacking (most are). The stack height must not exceed the container’s maximum stacking weight (usually about 120,000 lb for a standard 40‑ft). Always follow the container manufacturer’s stacking guidelines.

7. Quick Reference Cheat Sheet

- 20‑ft Standard: Ideal for small moves (≈1,172 cu ft).

- 20‑ft High Cube: Same footprint, extra height (≈1,300 cu ft).

- 40‑ft Standard: Most common for freight (≈2,390 cu ft).

- 40‑ft High Cube: Best all‑rounder for volume (≈2,570 cu ft).

- 45‑ft, 48‑ft, 53‑ft High Cube: Choose when you need a spacious interior but still require road‑legal dimensions.

- Reefer, Open‑Top, Flat‑Rack: Specialty options for temperature‑sensitive items, tall loads, or oversized equipment.

8. Final Thoughts

You now have a complete toolbox to assess shipping container sizes for any purpose—whether you’re moving a houseful of belongings, setting up a temporary storefront, or building a compact living space. Remember to:

- Measure the volume you truly need.

- Check weight limits and site access.

- Factor in cost per TEU and any specialty fees.

- Stay compliant with local regulations.

By following the steps and tables above, you’ll avoid the common pitfalls of choosing a container that’s either too small, too large, or simply unsuitable for your project’s logistics.

Now that you’re equipped with the facts, go ahead and make an informed decision—your next container could be the perfect “box” that unlocks your project’s potential. Happy shipping! 🚢✨