The Ultimate Guide to Setting Up a Container Office

You’re looking for a flexible, affordable, and fast‑to‑deploy workspace. A container office might be the perfect answer. In this post you’ll discover everything you need to know before you roll out a steel box and turn it into a fully functional office: from design possibilities and cost breakdowns to installation steps, legal considerations, and maintenance tips.

Below you’ll find tables, check‑lists, and a handy FAQ that will help you decide whether a container office fits your business, and how to get it up and running without a hitch.

1. Why Consider a Container Office?

| Benefit | What It Means for You |

|---|---|

| Speed of deployment | A conventional build can take months; a container office arrives on a truck and can be ready for occupancy in 2‑4 weeks. |

| Cost efficiency | Construction, labor, and material costs are typically 30‑50 % lower than a comparable brick‑and‑mortar space. |

| Mobility | Need to relocate? You can move the entire unit to a new site with a crane and a trailer. |

| Scalability | Stack or side‑join units to expand capacity as your team grows. |

| Sustainability | Re‑using shipping containers reduces waste and often qualifies for green‑building credits. |

| Customizability | Interiors, windows, doors, HVAC, and even smart‑office tech can be tailored to your brand. |

If any of these points resonate with you, a container office is worth a deeper look.

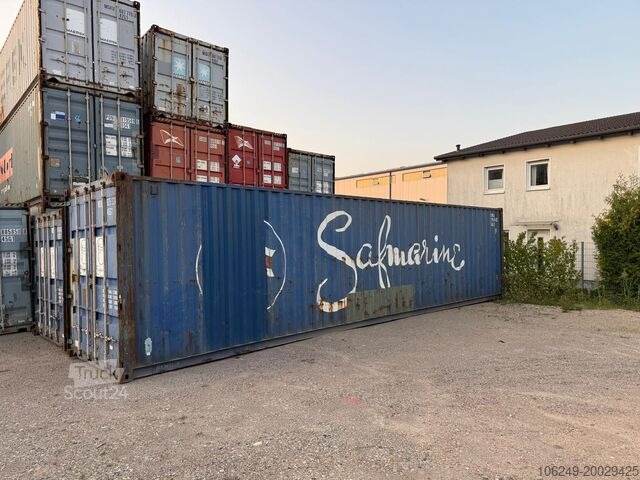

2. Choosing the Right Container Type

The two most common sizes are 20‑foot and 40‑foot containers. Your choice will hinge on the number of occupants, the type of work performed, and the site constraints.

| Dimension | Interior Floor Area | Typical Occupancy | Best For |

|---|---|---|---|

| 20‑ft (6 m) | ~13 m² (140 sq ft) | 2‑4 people | Small teams, meeting rooms, satellite office |

| 40‑ft (12 m) | ~27 m² (290 sq ft) | 5‑8 people | Full‑time office, workshop, studio |

Both sizes can be high‑cube (9.5 ft tall) for extra headroom, which is especially useful if you plan to install mezzanines or tall cabinets.

3. Cost Breakdown – What Will Your Budget Look Like?

Below is a realistic cost estimate for a fully fitted 40‑ft high‑cube container office in the United States (prices in 2024 USD). Numbers vary by region, custom finishes, and vendor, but this table gives you a solid baseline.

| Item | Low‑End | Mid‑Range | High‑End |

|---|---|---|---|

| Base container (new, high‑cube) | $2,500 | $3,500 | $5,000 |

| Insulation & interior wall finishes | $1,200 | $2,200 | $3,800 |

| Electrical & lighting (incl. wiring, sockets) | $800 | $1,500 | $2,500 |

| HVAC (mini‑split system) | $1,000 | $2,000 | $3,200 |

| Windows & doors (double‑glazed) | $600 | $1,200 | $2,000 |

| Flooring (carpet tiles/epoxy) | $300 | $700 | $1,200 |

| Furniture & ergonomic chairs (per seat) | $250 | $500 | $900 |

| Permits & site work (foundation, utility hookup) | $500 | $1,200 | $2,500 |

| Total (per unit) | $7,150 | $12,800 | $21,100 |

Tip: If you’re on a tight budget, consider a partially pre‑finished container and handle interior upgrades yourself. Many vendors also offer bundle discounts for multiple units.

4. Step‑by‑Step Checklist: From Concept to Occupancy

Below is a practical to‑do list you can print and tick off as you progress.

- Define Your Requirements

- Number of workstations

- Desired amenities (kitchenette, restroom, storage)

- Required certifications (e.g., LEED, OSHA)

- Select a Supplier

- Verify ISO‑9001 or similar quality certification

- Request sample photos of previous projects

- Compare warranty terms (typically 5‑10 years for the steel shell)

- Secure the Site

- Obtain a building permit from the local planning department

- Prepare a level foundation (concrete pad, steel frame, or crushed stone)

- Finalize Design & Layout

- Use a CAD or BIM model to visualize the interior

- Choose interior finishes (wall panels, flooring, ceiling)

- Plan the HVAC load based on climate zone

- Place the Order

- Confirm lead time (usually 4‑6 weeks for a standard spec)

- Arrange delivery logistics (truck length, access roads)

- Installation

- Unload the container onto the foundation

- Connect electrical and water services (often via a conduit box)

- Install insulation, drywall, and fixtures

- Commissioning & Inspection

- Test HVAC, lighting, and fire‑safety systems

- Invite the local building inspector for final approval

- Move‑In & Ongoing Maintenance

- Conduct a deep cleaning before occupancy

- Schedule annual rust check and resealing of any paint chips

5. Design Ideas to Make Your Container Office Feel Like a Real Office

- Open‑Plan Layout: Use modular desks on a raised platform to create a sense of space.

- Glass Walls: Replace one side with a floor‑to‑ceiling glass panel to flood the interior with natural light.

- Green Roof or Vertical Garden: Install a lightweight planter on the roof or an interior living wall for a biophilic touch.

- Smart Controls: Integrate IoT sensors for temperature, occupancy, and air quality that you can manage from a mobile app.

Pro Tip: Because steel conducts temperature, adding a reflective roof coating and thermal break insulation dramatically reduces heating/cooling costs.

6. Legal & Regulatory Considerations

| Regulation | What You Need to Do |

|---|---|

| Zoning | Confirm that the land is zoned for commercial/industrial use. |

| Building Code | Follow the International Building Code (IBC) or local equivalent for structural modifications. |

| Fire Safety | Install a fire‑extinguishing system (e.g., CO₂ or dry‑chemical) and ensure at least one emergency exit with a panic bar. |

| Accessibility (ADA) | Provide a ramp or lift if the office is open to the public or employees with disabilities. |

| Environmental | If you plan a green roof, obtain a storm‑water management permit. |

Consult a local architect or contractor early to avoid costly re‑work.

7. Frequently Asked Questions

Q1: How long does it take to get a container office from order to move‑in?

A: Typical lead time is 4‑6 weeks for a standard spec. Adding custom interior finishes can extend it by 2‑4 weeks.

B: The biggest time‑saver is finalizing the site foundation and utility connections before the container arrives.

Q2: Can a container office be used as a permanent workspace?

A: Absolutely. With proper insulation, HVAC, and compliance with local building codes, a container office can serve as a long‑term office space. Many startups and remote‑work hubs operate this way.

Q3: What are the main maintenance tasks?

A:

- Inspect the exterior paint and reseal any chips every 2‑3 years.

- Check door seals and window frames for water ingress.

- Service the HVAC system annually.

- Clean the interior filters and replace them as recommended (usually every 6‑12 months).

Q4: How does a container office compare to a modular prefab building?

A:

| Feature | Container Office | Modular Prefab |

|---|---|---|

| Cost per sq ft | $150‑$250 | $250‑$350 |

| Lead time | 4‑8 weeks | 8‑12 weeks |

| Mobility | High (can be relocated) | Low (usually fixed) |

| Structural strength | Steel frame, high durability | Steel or wood frames, varies |

| Design flexibility | Moderate (mostly rectangular) | Very high (custom shapes) |

If you need a quick, mobile solution, go with a container. If you want complex geometry or higher ceilings, a modular prefab may be better.

Q5: Is financing available for container offices?

A: Many providers partner with equipment‑leasing companies, offering lease‑to‑own options with 3‑5 year terms. Some local banks also provide construction loans for portable structures.

8. Real‑World Success Stories

- Tech Startup “PixelForge” (Austin, TX) – Deployed three 40‑ft high‑cube containers as a 12‑person dev hub in 2023. Cost: $38,000 total, 70 % less than a leased office space.

- Healthcare Clinic “Wellness First” (Portland, OR) – Used a 20‑ft container for a walk‑in triage station. The container was fitted with a medical‑grade HVAC system and a stainless‑steel interior.

- Construction Company “BuildRight” (Manchester, UK) – Set up a portable site office on a remote development site, allowing project managers to be on‑site 24/7 without building a permanent office.

These case studies illustrate the adaptability of container offices across industries.

9. Bottom Line: Is a Container Office Right for You?

If you value speed, cost‑efficiency, and flexibility, a container office ticks all the boxes. By following the checklist above, you can avoid common pitfalls—such as neglecting permits or under‑insulating the space—and enjoy a modern workspace that reflects your brand’s innovation.

Remember: the success of a container office isn’t just about the steel shell; it’s about how you customize, maintain, and integrate it into your operational flow.

Ready to take the next step? Reach out to a reputable container‑office supplier today, and start sketching the interior layout that will make your team feel right at home—inside a box that’s anything but ordinary.

Quick Reference Summary

| Aspect | Key Takeaway |

|---|---|

| Size choice | 20‑ft for 2‑4 people; 40‑ft for 5‑8 people. |

| Cost range | $7k (basic) → $21k (premium) per unit. |

| Lead time | 4‑8 weeks (standard), 6‑12 weeks (custom). |

| Major costs | Container shell, insulation, HVAC, permits. |

| Maintenance | Paint & rust check, HVAC service, filter replacement. |

| Legal | Zoning, building code, fire safety, accessibility. |

| Mobility | Easy relocation with crane/trailer. |

| Sustainability | Re‑uses shipping containers, qualifies for green credits. |

Feel empowered to explore this versatile solution—your future office may just be a container away.